Sandblast Marking

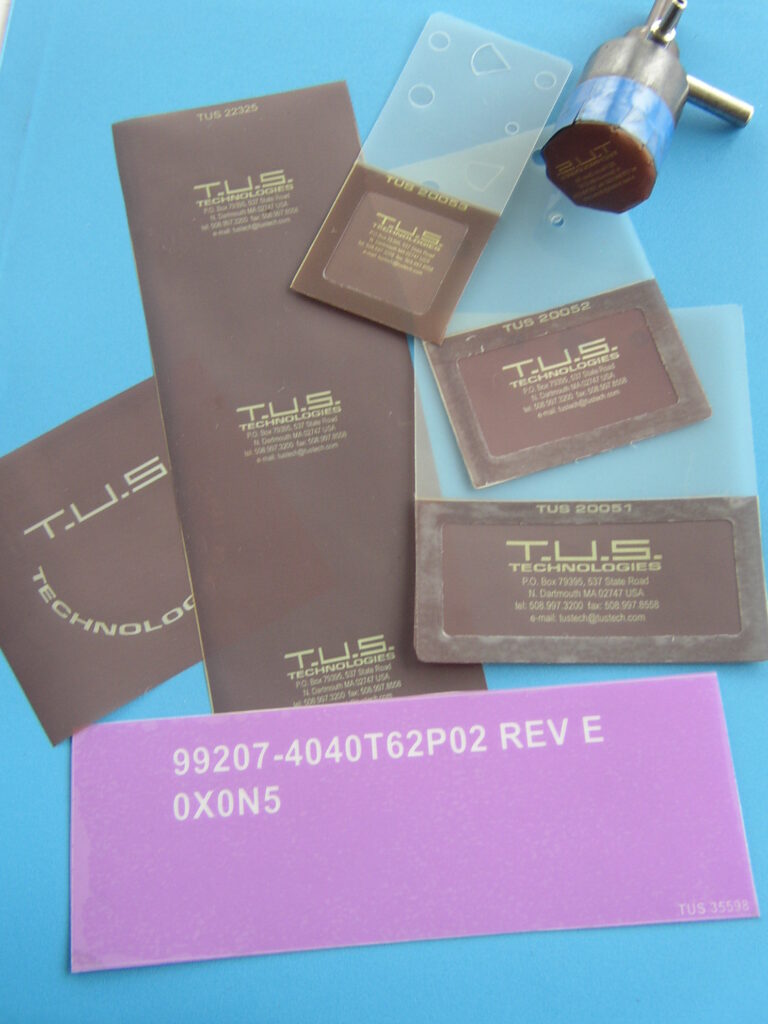

TUS produces sandblasting stencils in a variety of shapes and materials. We will work with you from the choice of the right material to the correct layout and inscription of the mark. The stencils will come ready to use, they have an adhesive backing and a transfer tape (if applicable). Our sandblasting stencils are one time use stencils.

Sandblasting is used for a variety of materials – for each material we have a suitable solution for your requirements.

Sandblast Marking Service

TUS can accomplish the part identification and serialization for parts to be marked by sandblasting, also called grid blast marking. We have all common marking standards for aerospace or defense parts on hand. Our expertise ranges from regular inscriptions to 2d-barcodes. We can mark all surface shapes from straight to round or spheric.

TUS has an extensive sandblast marking operation and we cooperate with a multitude of aircraft and turbine manufacturers.

Sandblast marking stencils for machined metal parts and glass

TUS offers sandblast stencils for your inhouse marking operation. The material we provide is a membrane stencil that offers great reproduction of details and fine lines. We suggest a minimum font height of 0.1″. The material is specifically made for sandblasting high quality surfaces like machined metal surfaces or glass. You will receive detailed instructions incl. pressure, blasting media with your stencils.

sandblasting stencils for concrete, granite, rock and large metal surfaces

TUS offers ready to be used stencils from cut materials. Thickness of the stencil material ranges from 10 to 42mil. The thicker stencils are made for concrete and rock and have an aggressive backing, suitable for most concrete, granite or rock surfaces. For specifically uneven or dirty surfaces we will come up with a recommendation for a filler material for additional adhesion forces. TUS has an extensive track records for this type of application.

We have produced multiple extra-large sandblasting schemes like maps and patterns with sizes of 100ft+ in one dimension.

F.A.Q.

Frequently asked questions about sandblasting or grid blast marking

These stencils are made for marking metal surfaces, glass or similar materials. Use 20-40 psi for pressure pot systems or 60-80 psi for suction systems. The finer the media, the better the detail reproduction. We recommend 100 grit or finer.

You are applying too much air-pressure. Start with 80 psi and work your way up.

We do not offer reusable blast stencils and we are not aware of any viable solutions for metal, glass or other surfaces.